The major WTP system components are designed and manufactured/constructed by the Company’s key partners, many with decades of high-tech R&D and manufacturing experience and strong records of timely contract completion and product support. We have established strategic and technical alliances with key waste diversion companies and OEMs with distinct but complementary capabilities, collectively providing the resources required to execute projects tailored to meet communities’ waste disposal needs, including but not limited to:

- Engineering firms specializing in renewable energy, waste management, and resource recovery systems;

- Technology companies that have developed improved process efficiencies for anaerobic digestion; and

- Full-service EPC contractors providing construction services, fabrication, and engineering solutions to the Power & Energy and Waste Diversion sectors with track records of success in the U.S., Canada, and abroad.

Outputs that can be produced include:

- Green electrical power—to the end-user or the grid

- Liquid fuels—including biogas, drop-in biodiesel, to end-user or the pipeline

- Soil amendments, fertilizers

- Carbon black and other marketable commodities

Treated water

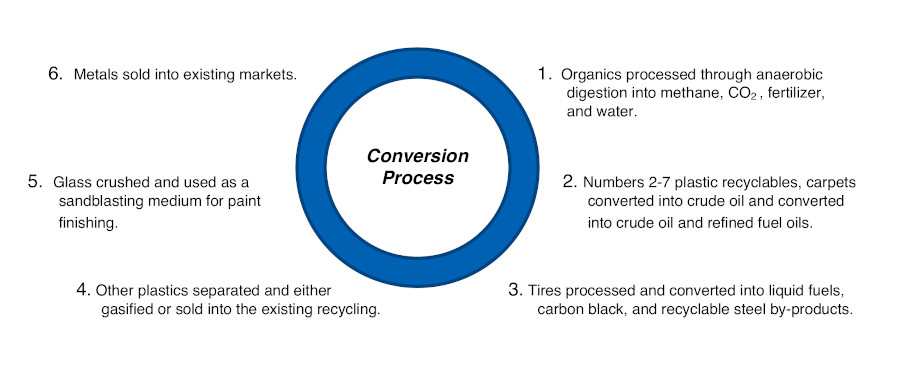

WTP’s waste treatment systems integrate specialized, highly efficient fourth-generation anaerobic Our waste diversion systems integrate specialized, highly efficient fourth-generation anaerobic digestion processes and machinery utilized in the waste management industry to 1) remove the high-value recyclables for resale and 2) process the remaining solid waste fraction into a valuable renewable energy feedstock (typically, biogas and electricity) and/or beneficially used as a soil amendment or for daily cover at the landfill. Non-recyclable plastics (Numbers 3-7) are pyrolyzed separately and converted into crude oil and refined into fuel oils. With the targeted recyclables removed from the waste stream and post-digestion, the volume of the remaining waste material going to the landfill is dramatically reduced and stabilized—typically < 5% of waste by-products are returned to landfill as inert material.

The demands of processing complex feedstocks don’t afford the luxury to engineer, design and manufacture one piece of equipment to handle the task. Feedstocks such as MSW have multiple densities and moisture levels—everything from cardboard and green waste to food waste and other organic material, to metals and plastics. (Metals are removed before the digestion stage begins.) The WTP process integrates state-of-the-science, field-proven OEM process equipment to meet the requirements of the client’s waste stream.

The general conversion process, depending on the waste stream: